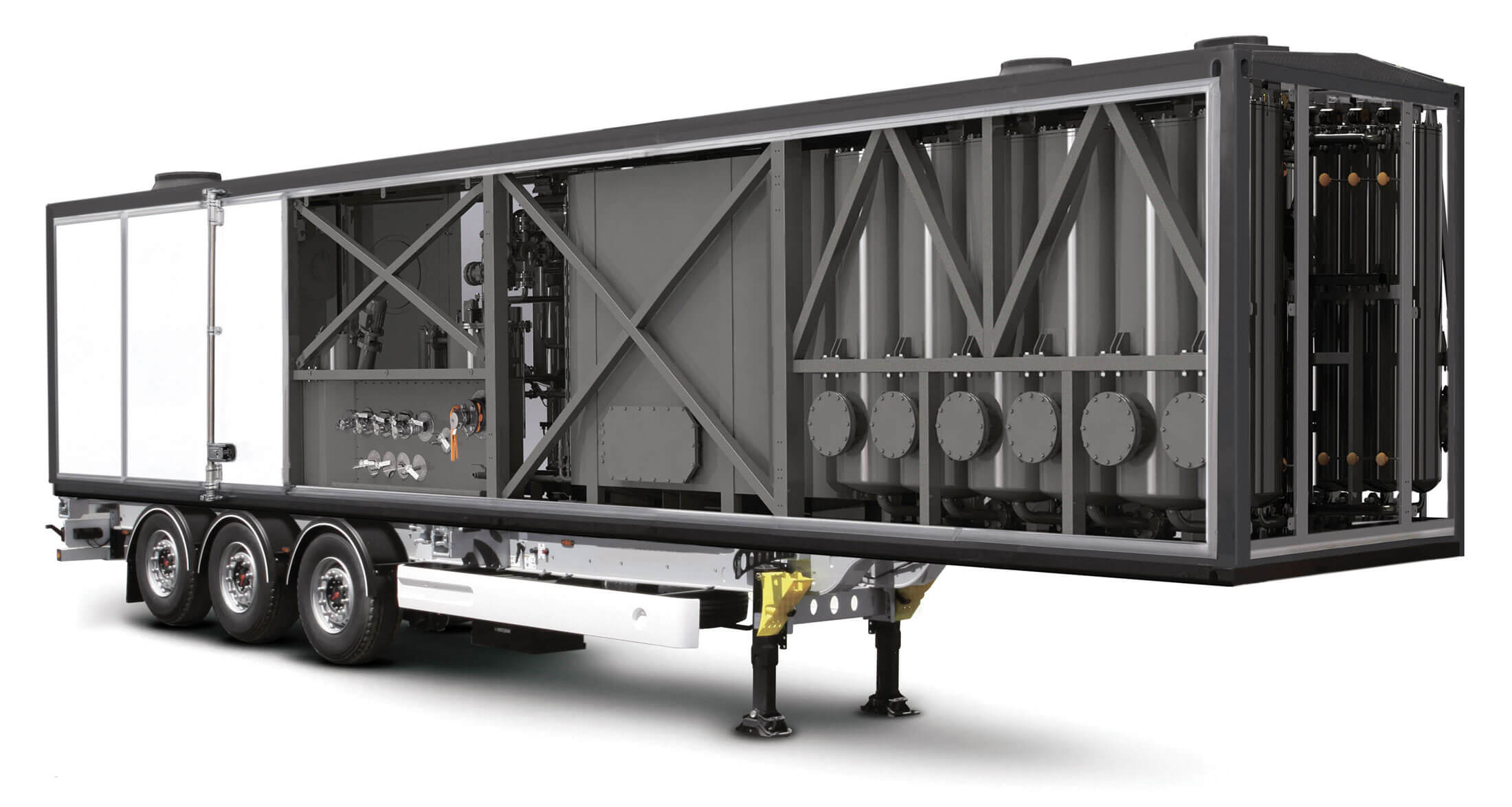

CMM-4RP Adsorbent reactivation unit

Adsorption purification of petroleum products improves their chemical and physical properties and does not alter the composition of the products. The process removes unsaturated and aromatic hydrocarbons, tar, nitrogen, sulfur, and oxygen-containing compounds.

The effect is due to the absorbent’s ability to capture and retain contaminants. Over time, the adsorption rate decreases and stops when a certain equilibrium is reached. At this point, the absorbent needs to be replaced or reactivated.

Existing methods of absorbent reactivation are characterized by significant losses of absorbent (up to 30%) and processed product. These factors prompted GlobeCore to develop CMM-4RP units for absorbent reactivation for oil purification.

This equipment is designed for restoring saturated absorbents used in oil purification processes. Using the CMM-4RP can potentially save on purchasing new absorbent and disposing of the old absorbent.

Saturated absorbent is loaded into special columns, where it is subjected to high temperature and vacuum, removing contaminants. Once the reactivation process is complete, the columns are reversed, and the restored absorbent is discharged. The oil captured by the absorbent is collected in a special container and can be reused.

Reactivating used absorbents allows for the restoration of their properties and their use in purifying petroleum products with varying degrees of contamination.

The design and production of the unit can be customized. In this case, the lead time is 45 days. Stock models of absorbent regeneration units can be purchased directly.

If necessary, our specialists can visit your facility to commission the unit and train your staff.

FREQUENTLY ASKED QUESTIONS:

- Which absorbents can be reactivated using the CMM-4RP?

This equipment can be used to reactivate fuller’s earth, various bleaching clays, palygorskite, etc.

- How much absorbent is lost during reactivation?

Less than 3-10%.

- How long does the reactivation process take?

Up to 20 hours.

- How much absorbent can be reactivated in one cycle?

Up to 300 kg.

- What should be done if the reactivation process does not start in one of the columns?

All columns operate separately. In this case, the problematic column is disconnected, and the process continues in other columns.

- What is the equipment warranty?

12 months from the date of commissioning.

| No. | Parameter | Value |

| 1 | Rated Power, kW | 18 |

| 2 | Total Electrical Consumption per Reactivation Cycle, kWh | 70 |

| Voltage, V | Customized | |

| 4 | Control System | Semi-automated |

| 5 |

Dimensions, mm – length – width – height |

2800 2150 2150 |

| 6 | Weight, Kg | 2200 |

- Complete removal of oil captured by the absorbent.

- Reuse of the absorbent up to ten times after reactivation.

- Reactivated absorbent can purify products with any degree of contamination.

- Reduced absorbent reactivation costs.

- Reduced transportation expenses.

- The absorbent can be deactivated during disposal without harmful effects on the environment.

Zeolite Regeneration Units ...

Zeolite Regeneration Units ... BRPS Zeolite Regeneration ...

BRPS Zeolite Regeneration ... CMM-R Oil regeneration ...

CMM-R Oil regeneration ...