INDUSTRIAL DISINFECTANT MAKING MACHINE USB-5

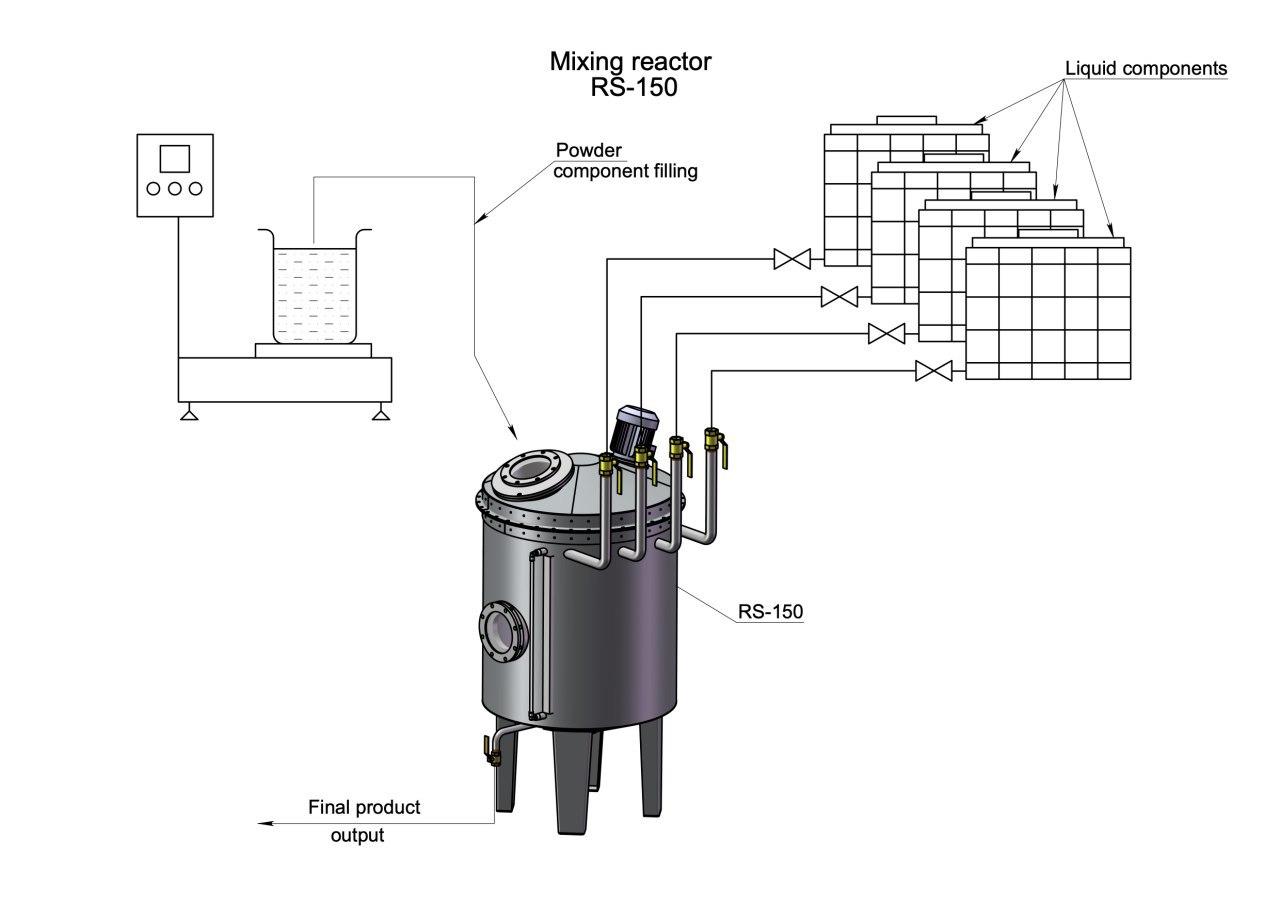

Traditionally antiseptics and disinfectants are made in large vessels where mechanical agitators are used to mix several ingredients into a finished products. To do away with the big tanks, reduce equipment footprint and modernize it, GlobeCore has developed USB-5 disinfectant making machine.

The principal of operation is simple, a pump feeds the main ingredient – alcohol into a nozzle of a mixer. The nozzle has a narrowing cone to change the velocity of the flow, this creates vacuum in the mixing chamber. The vacuum sucks in the other ingredients from storage tanks. The ingredients are blended in a turbulator. The finished product is supplied through an outlet line to bottling or storage.

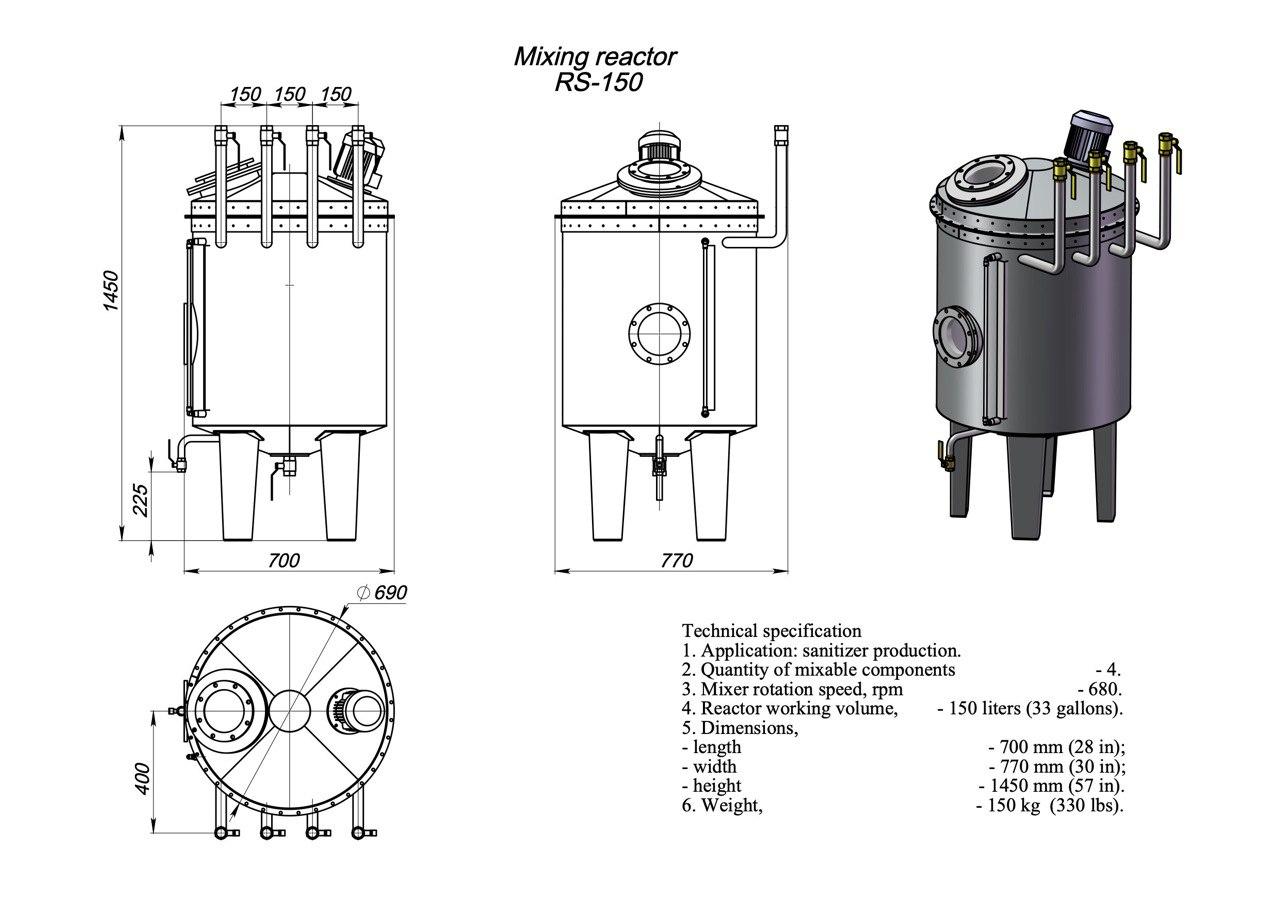

| 1 | Application | Sanitizer production |

| 2 | Quantity of mixable components | 4 |

| 3 | Mixer rotation speed, rpm | 680 |

| 4 | Reactor working volume: | 150 liters (33 gallons) |

| 5 | Dimensions,- length- width- height |

– 700 mm (28 in);– 770 mm (30 in);

– 1450 mm (57 in) |

| 6 | Weight |

– 150 kg (330 lbs) |

Fuel blending systems

Fuel blending systems Biodiesel equipment

Biodiesel equipment Electromagnetic mill AVS-150

Electromagnetic mill AVS-150