Transformer vacuum furnace

Transformer’s service life depends on the prompt service and maintenance. GlobeCore is ready to present new unit for drying the solid insulation in power transformers.

During the transformers work insulation accumulates water, which causes reduction of dielectric strengths up to 20 times.

There are some different ways of removing moisture from oil. We can advice you drying with the vacuum furnace, because it has such advantages as:

- accelerated moisture evaporation comparing with warm air drying;

- general optimization and shortening of the processing time;

GlobeCore meets customers needs and offers the vacuum furnace with various modifications adapted to the particular conditions. Construction is designed with consideration of the size, capacity, location on a site and ways of transportation.

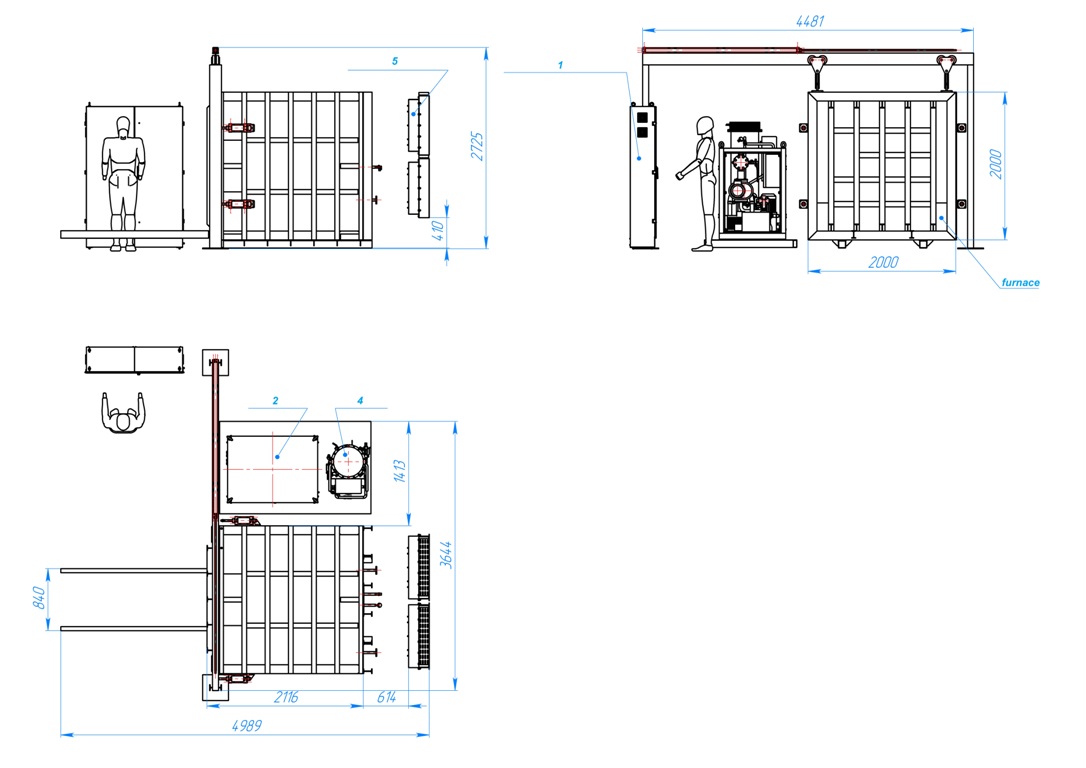

Design

- Control cabinet;

- Vacuum module BV-1000;

- Oil heater PPM-18;

- Vapour condenser;

- Condensate collection reservoir;

- Furnace chamber.

Operation process

Firstly the active part of a transformer must be loaded to the carriage by a loader or a crane. Then the operator controls the movement of carriage, which is activated by a motorized drive, and closing and opening the doors of the furnace chamber.

Heating of the furnace chamber is provided by the technical oil. To reach the necessary temperature for heating, oil passes through the heater.

Additional options

Besides that, GlobeCore manufactures vacuum drying chambers for other materials:

- wood;

- food products;

- pastes and powders.

- drying of the entire surface of a transformer core;

- energy efficiency;

- shortened time for drying;

- easy to operate;

- removal of moisture from chamber.