Against the backdrop of increasing vehicle traffic and axle load, as well as seasonal temperature fluctuations, asphalt concrete pavement quickly wears out, necessitating costly repairs.

This problem was solved by combining road bitumen with special additives, allowing for the creation of binders with the required properties. Modified bitumen provides greater strength to road surfaces, reduces the formation of cracks and potholes, thanks to its higher elasticity, resistance to high and low temperatures, and also contributes to forming a smooth and even road surface.

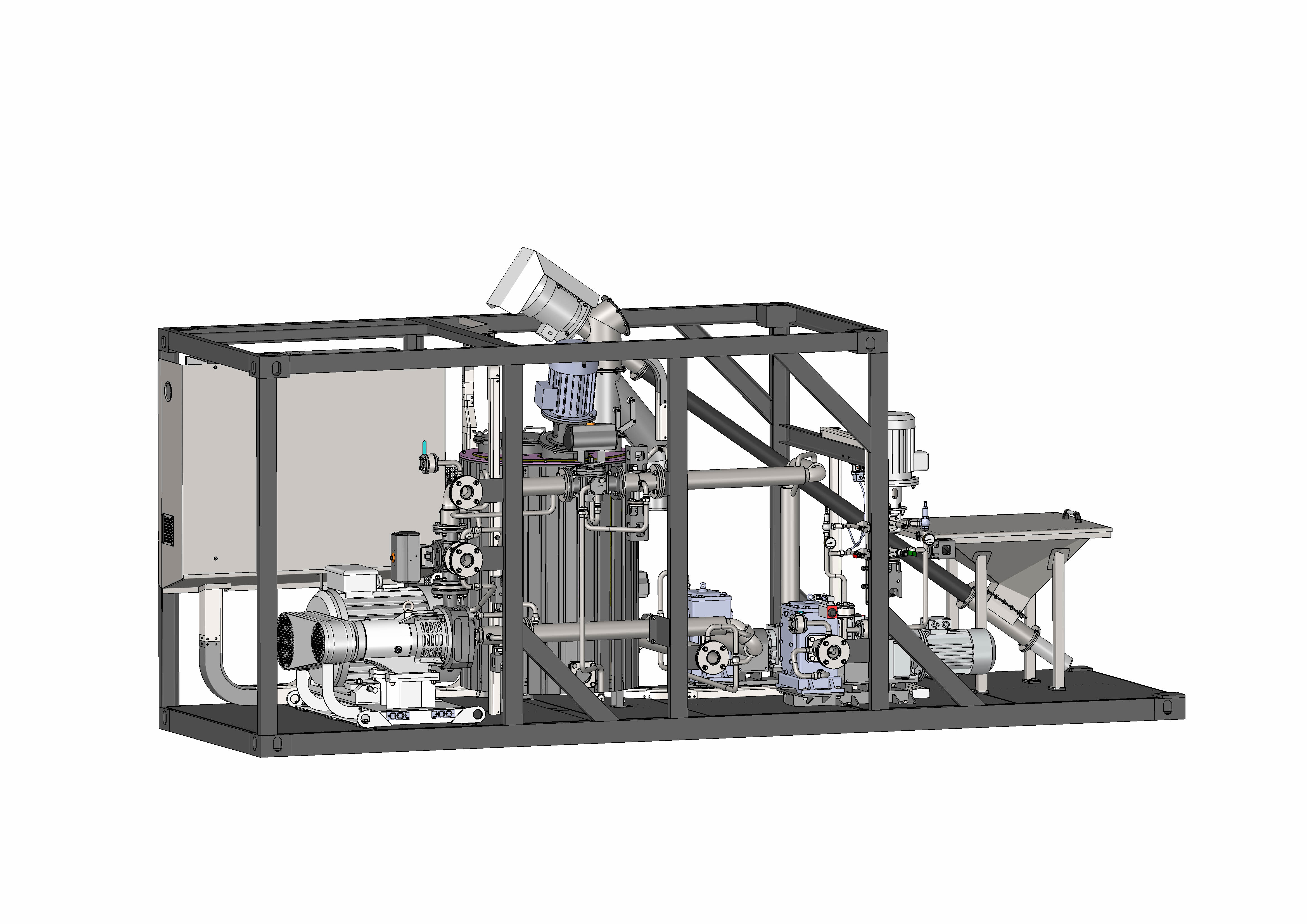

For bitumen modification, GlobeCore produces both batch and continuous action plants. In the batch process, modified bitumen is produced in cycles consisting of several consecutive operations. In the continuous process, technological operations are performed simultaneously, allowing for the production of modified bitumen in a continuous flow.

The USB-12P plant operates continuously. It modifies bitumen with any polymer additives in the form of powder, granules, or liquids with a capacity of 12 cubic meters per hour. The technology of the GlobeCore plant, implemented in the USB-12P, also allows the use of rubber crumb or polyphosphoric acid.

Operating the USB-12P plant enables the production of high-quality modified bitumen for large volumes of asphalt concrete mixes. Roads built with such mixes last 2-3 times longer than roads made with mixes using regular bitumen.