UVR – oil and fuel regeneration units

Globecore UVR units are universal equipment, which is designed and used for: regeneration of various types of oils – thermal, transformer, turbine, industrial, hydraulic as well as for clarifying fuel – diesel fuel, furnace fuel, gas condensate, gasoline, kerosene, etc.

Absolutely any of the UVR machines are versatile to work, clean, brighten, regenerate and remove aromatics from absolutely all oil products. Installation can be applied to any enterprise, does not require special placement, is easily transported, and noiseless.

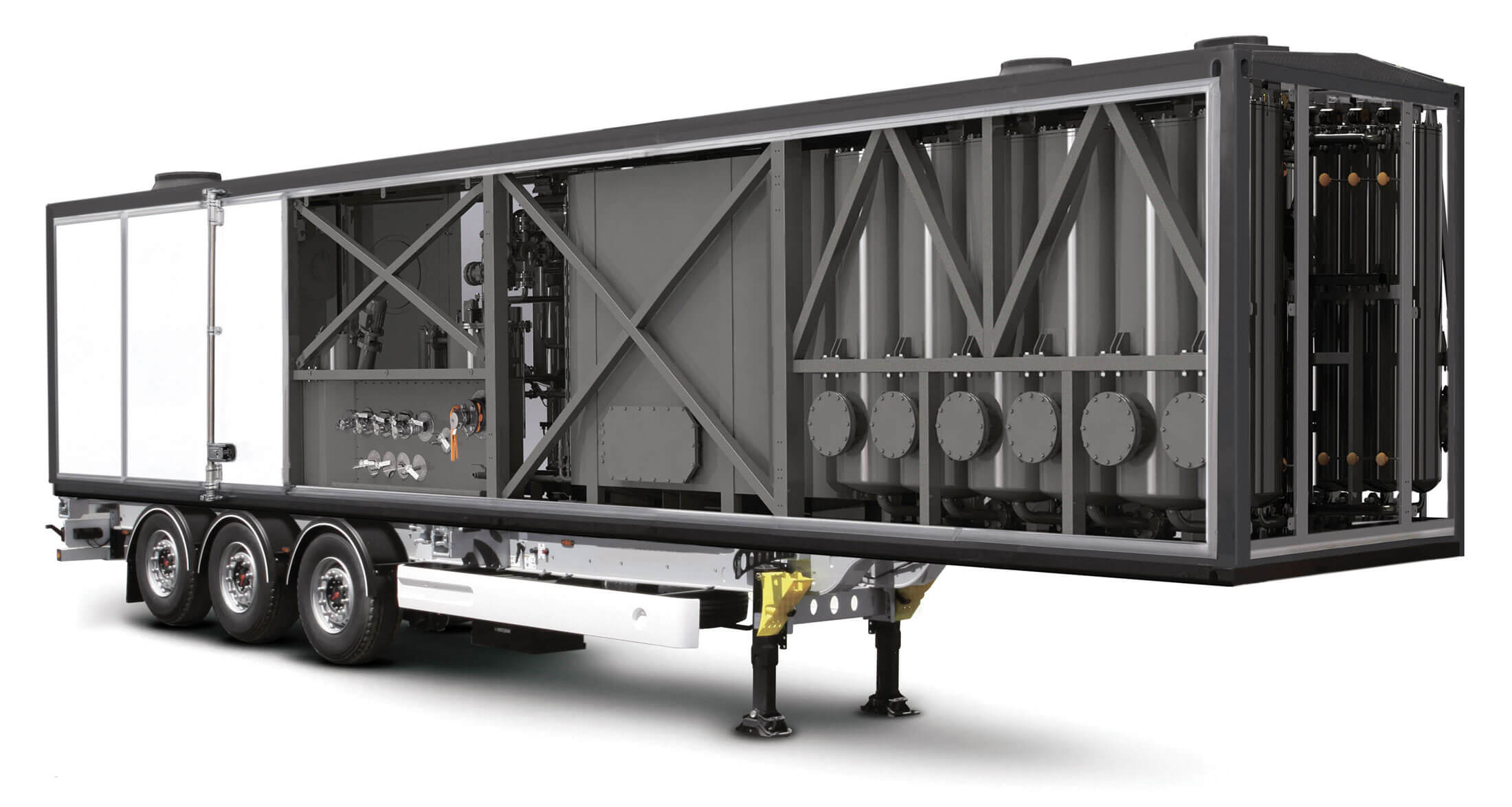

UVR can be made in one of the three types of form:

- common industrial frame;

- general industrial container;

- fire and explosion proof (rolling container).

Technical characteristics of UVR units

GlobeCore takes a leading position in the market of manufacturers of cleaning equipment for oil purification and regeneration of various mineral oils, filtering and refining diesel fuels, clarifying furnace fuels and other hydrocarbon liquids, the unit also removes aromatics, mercaptans, hydrogen sulfide, partially sulfur (desulfurization).

Over the years of its existence, the plant has developed, modernized and put into serial production dozens of units of filtering, purifying, clarifying and regenerating equipment, the company also has vast experience in the implementation of this equipment at various industrial facilities.

Petroleum products after the process of regeneration, clarification or purification maintain their stability and do not darken.

The UVR unit cleans and brightens dark diesel and heating oil, removes sulfur and hydrogen sulfide compounds, easily cleans gas condensate from tar and contaminants, after cleaning the fuel, it meets standards and high purity class, removes unpleasant odors such as hydrogen sulfide and other aromas.

The unit is compact, has a built-in control panel, which at the request of the customer can be made remote and located remotely (in the operator room, for example). The UVR can operate in two modes, “automatic” and “manual”.

Unit does not require special placement on the foundations, a fairly flat surface is enough or you can set the installation on the pylons. The actual consumed amount of electric power is 2-3 kW / h, when the heating of the filter elements is not involved.

However, the preferred factor is the location under a canopy or in a hangar (room), the containerized version can be operated without a canopy or a room/hangar.

All units at the plant are calibrated and tested for performance with already used contaminated transformer oil!

| Oil Processing | Rate Per Hour m3/gals. |

| UVR-450/6 | 0.08/21.2 |

| UVR-450/16 | 0.2 /53 |

| UVR-450/16K | 0.2 /53 |

| Parameter | Value | |||

| Regeneration capacity, m3/hour/gals. per hour: | UVR-450/6 | UVR-450/16 | UVR-450/16/k | UVR-450/16/v |

| • transformer oil | 0.08-0.1/21.2 | 0.20-0.27/53.0-71.5 | 0.20-0.27/53.0-71.5 | 0.20-0.27/53.0-71.5 |

| • turbine oil | 0.08-0.1/26.5 | 0.20-0.27/ 53.0-71.5 | 0.20-0.27/ 53.0-71.5 | 0.20-0.27/53.0-71.5 |

| • industrial oil | 0.08-0.1/26.5 | 0.15-0.20/39.2-53.0 | 0.15-0.20/39.2-53.0 | – |

| • dark fuel oil | 0.25/66.2 | 0.6-0.8/159-213 | 0.6-0.8/159-213 | 0.6-0.8/159-213 |

| • dark diesel fuel | 0.25/66.2 | 0.6-0.8/159/213 | 0.6-0.8/159/213 | 0.6-0.8/159/213 |

| • dark gas condensate | 0.30/19.4 | 0.7-1.1185/291 | 0.7-1.1185/291 | 0.7-1.1185/291 |

| Consumption of regeneration powder as % of processed product weight

• transformer oil • turbine oil |

3-17

3-17 |

3-17

3-17 |

3-17

3-17 |

3-17

3-17 |

| • industrial oil | 3-17 | 3-17 | 3-17 | – |

| • dark fuel oil

• dark diesel fuel • dark gas condensate |

2-15

1-7 1-5 |

2-15

1-7 1-5 |

2-15

1-7 1-5 |

2-15

1-7 1-5 |

| Regeneration poweder load | 20 /44.2 | 20 /44.2 | 20 /44.2 | 20 /44.2 |

| • one regeneration pod, kg/lbs | ||||

| • all regeneration pods, kg/lbs | 120/265.2 | 320/707.2 | 320/707.2 | 320/707.2 |

| Loss (of oil product) % of initial volume (remains in the sorbent)

• transformer oil • turbine oil |

1-6

1-6 |

1-6

1-6 |

1-6

1-6 |

1-6

1-6 |

| • industrial oil | 1-6 | 1-6 | 1-6 | 1-6 |

| • dark fuel oil

• dark diesel fuel • dark gas condensate |

1-6

1-6 1-6 |

1-6

1-6 1-6 |

1-6

1-6 1-6 |

1-6

1-6 1-6 |

| Total power of heaters, kW | 1.98 | 5.28 | 5.28 | – |

| Nominal power, kW | 5 | 8 | 13 | 8 |

| Power consumption with heating off, kWh | 3 | 2.72 | 7.7 | 5 |

| Filtration fineness, in microns | 500 | 500 | 500 | 500 |

| • inlet | ||||

| • outlet | 5 (3) | 5 (3) | 5 (3) | 5 (3) |

| Three phase 50(60) Hz power voltage, V | 380 | 380 | 380 | 380 |

| Dimensions, mm/ft, length/ width/ height | 1 section | 1 section | container | 1 section |

| 2600/1500/2030 | 4800/1500/2140 | 6060/2590/2440 | 4800/1500/2140 | |

| 8’6”/4’11”/6’8” | 15’9”/4’11”/7’ | 19’11”/8’6”/8’ | 15’9”/4’11”/7’ | |

| Weight, kg/lbs | 1100/2,431 | 2350/5,193.5 | 7000/15,470 | 3400/7,514 |

By choosing an automatic or semi-automatic mode, the constant presence of the operator is no longer required, it is only necessary when you want to start or stop the unit or to replace the adsorbent.

Minimal energy consumption – real power usage while cleaning fuels in terms of kW is not more than 3 kW / h, one liter of product cost only a few cents.

The UVR is universal and does not require any complicated manipulations when changing cleaned, clarified or regenerated fuel or mineral oil type. To switch from one raw material to another, even if they are fundamentally different, for example, switching from oil clarification to oil recovery, you just need to stop the unit, switch to manual control, pump out the remaining oil from the system, replace the adsorbent, and filter elements.

Laboratory oil filtration ...

Laboratory oil filtration ... CMM-6R Light Transformer ...

CMM-6R Light Transformer ... CMM-R Oil regeneration ...

CMM-R Oil regeneration ...